LIQUID WASTE TREATMENT & RECYCLE

Advanced aerobic technology produces treated water that is continuously of highest quality, allowing for safe effluent discharge and stable process performance. Anaerobic technologies with high removal efficiency of organic matter, are particularly suited to treat highly concentrated waste waters such as from brewery, distillery, tannery, paper, fermentation and pharma industries.

Waste water recycle technologies include advanced membrane processes such as the membrane bio-reactor which produces an effluent that is extremely pure and appropriate for immediate reuse, as well as the fluidised media reactor and packaged sewage treatment systems.

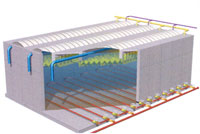

LUCAS® Aerobic

LUCAS® Aerobic combines the advantages of the conventional and the sequencing batch reactor technology. Like in the conventional system, the reactor volume and the level in the tanks is always constant. It is a continuous system for both influent feed and effluent discharge. Like in the fill-and-draw system, the reactor operates according to a time-controlled process cycle that allows for the alternation of all essential processes in a single compartment. By using the most advanced processes in combination with the autonomous monitoring and controlling system, the treated water will be continuously of the highest quality. This allows for safe effluent discharge and stable process performance. No external clarifiers, sludge rakers, recycle pumps/screws/piping are needed and reactor volume is always used for 100%. In addition the system can be easily controlled and the treatment efficiency is very high (80 – 95%).

Download pdf leaflet

LUCAS® Anaerobic

LUCAS® Anaerobic is the brand name for an anaerobic waste water treatment system which uses Upflow Anaerobic Sludge Blanket, Upflow Anaerobic Contact, Anaerobic Filtration and Hybrid Anaerobic Filtration technologies for treating waste water depending on specific requirement. The LUCAS® Anaerobic technology is typically applied as a first stage to remove on an average 85% of the COD (Chemical Oxygen Demand) out of the water. This technology is particularly suited to treat highly concentrated wastewaters rich in carbohydrates and carboxylic acids such as brewery waste waters and waste waters derived from the soft drink and malthouse industry. Depending on the characteristics of the brewery or soft drink wastewater, a high removal efficiency of the organic matter of 70-90% is achieved.

Download pdf leaflet

Based on the effluent limits that have to be met, the LUCAS® Anaerobic stage can be followed by a LUCAS® Aerobic stage to remove the remaining COD and to remove nutrients (N&P). The LUCAS® Anaerobic-Aerobic, where the anaerobic stage is followed by an aerobic stage, has been specifically developed to meet the needs of breweries and beverage companies. Both stages can be applied separately or in combination.

Advantages of LUCAS® Anaerobic-Aerobic with Nutrient Removal

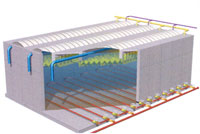

Submerged Membrane Bioreactor

Submerged Membrane Bioreactor

With the INDION Submerged

Membrane Bioreactor, the higher biomass concentrations

can be kept in a reactor causing a decrease of the bioreactor

volume with a factor 3-4 compared to a conventional sludge system.

Furthermore, the energy consumption is kept to minimum by placing

the hollow fibre membranes inside the reactor.

Download pdf leaflet

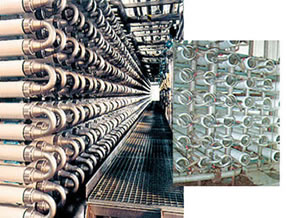

X-TRACTOR Crossflow Membrane Bioreactor

In the X-TRACTOR Crossflow Membrane Bioreactor, tubular membranes are placed outside in an external loop of the bioreactor. Due to the high-energy consumption, caused by the high-speed circulation, this crossflow concept is used to treat smaller but more difficult waste water flows.

Download pdf leaflet